Size (and Scale) Matter: Addressing Ostrom’s Critics

In his classic article “The Tragedy of the Commons,” Garrett Hardin famously declared that “ruin is the destination toward which all men rush, each pursuing his own best interest in a society that believes in the freedom of the commons.”1Garrett Hardin, “The Tragedy of the Commons,” Science 162, no. 3859 (December 1968): 1244. Elinor Ostrom disagreed.2Elinor Ostrom, Governing the Commons: The Evolution of Institutions for Collective Action (Cambridge: Cambridge University Press, 1990); Elinor Ostrom, Understanding Institutional Diversity (Princeton, NJ: Princeton University Press, 2005); Elinor Ostrom, “Beyond Markets and States: Polycentric Governance of Complex Economic Systems,” American Economic Review 100, no. 3 (June 2010): 641–72. She argued that, even in the absence of clearly defined and enforced private property rights or statist regulations, bottom-up arrangements have historically often been sufficient to prevent the overuse and destruction of common-pool resources (CPRs) such as pastureland, fisheries, forests, and irrigation systems.

Ostrom is celebrated for devising and championing the Institutional Analysis and Development framework. By collecting, systematizing, and analyzing numerous case studies, Ostrom paved the way for a more nuanced analysis of how, working collectively, economic actors can sustainably manage activities such as irrigation, fishing, forestry, and grazing outside the contexts provided by either well-defined private property rights or edicts from political or regulatory authorities. Both the supporters and the critics of Ostrom’s work generally agree that most of the examples of successful CPR management she gathered and analyzed relate to sparsely populated, remote, and economically stagnant rural or forested areas. These include some of the most economically marginal regions of advanced and developing economies3Ostrom et al., eds., The Drama of the Commons (Washington, DC: National Academy Press, 2002), https://doi.org/10.17226/10287. such as those of Japan, Switzerland, Spain, Turkey, and the Philippines.4Fikret Berkes, “Local-Level Management and the Commons Problem: A Comparative Study of Turkish Coastal Fisheries,” Marine Policy 10, no. 3 (1986): 215–29; Ostrom, Governing the Commons, chapter 3; Tamara L. Whited, Forests and Peasant Politics in Modern France (New Haven, CT: Yale University Press, 2000); Robert M. Schwartz, “Review of ‘Forests and Peasant Politics in Modern France,’” H-France Review 1 (December 2001): 199–203. Using fisheries as an example, distinguished Canadian applied ecologist Fikret Berkes demonstrated why the economically more modest CPRs tend to provide cases of spontaneous evolution of Ostromian cooperative frameworks more frequently than their larger counterparts: “While open-ocean, large-scale fisheries usually come under national and international levels of management, the small-scale coastal fisheries often operate outside the framework of measures instituted by central governments.”5Berkes, “Local-Level Management,” 216.

Ostrom’s preference for modest and marginal locations, so convincingly explicated by Berkes, has, nevertheless, supplied some ammunition to critics of her work. For instance, Swiss agricultural economist Philipp Aerni wrote that Ostrom was “fascinated by remote villages in the Swiss Alps that were governing the local commons sustainably without much trade and exchange with the outside world and without relying exclusively on private property rights.”6Philipp Aerni, “Food Sovereignty and Its Discontents,” ATDF Journal 8, no. 1/2 (2011): 23–40, 24. Yet, Aerni argued, this “lack of contact with the outside world also prevented these villages from adopting new techniques and innovative practices that would have enhanced their agricultural productivity.” He added that “local investment in innovation was also neglected because of the absence of ownership rights,” the result being stagnating agricultural productivity. Furthermore, Aerni contended, the equilibrium Ostrom described was historically possible only when the “surplus population (the population that could not be fed with the available resources and traditional techniques) could be exported as mercenaries to foreign armies or as non-farm labourers to lowland industrial centres,” in the process contributing remittances that “allowed the villagers to buy food from elsewhere during periods of scarcity.”7Aerni, “Food Sovereignty,” 24–25.

Taking a broader view of the issue, economist Ted Bergstrom similarly argued that “the real-world commons problems that Ostrom studies usually involve repeated interactions among a relatively small number of players who are able to develop subtle institutions for monitoring and enforcing a degree of cooperation.”8Theodore C. Bergstrom, “The Uncommon Insight of Elinor Ostrom,” The Scandinavian Journal of Economics 112 (2010): 245-261, https://doi.org/10.1111/j.1467-9442.2010.01608.x, 246. Bergstrom was skeptical that such a local, polycentric approach can prove useful when dealing with a problem of global scope, such as climate change caused by unmonitored carbon dioxide emissions.

Prominent Marxist geographer David Harvey similarly questioned the scalability of communal solutions, pointing out that “most of [Ostrom’s] examples . . . involve as few as a hundred or so appropriators. Anything much larger (her largest case involved fifteen thousand users) required a ‘nested hierarchical’ structure of decision making, rather than direct negotiations between individuals.”9 David Harvey, “The Future of the Commons,” Radical History Review 109 (2011): 102. Therefore, Harvey argued, there is an “unanalyzed . . . scale problem” in Ostromian solutions for the “possibilities for sensible management of common-property resources that exist on one scale, such as shared water rights between one hundred farmers in a small river basin, do not and cannot carry over to problems such as global warming or even to the regional diffusion of acid deposition from power stations.” When attempting to translate a solution to one problem to another at a different scale, however, the “whole nature of the common-property problem and the prospects of finding a solution change dramatically,” because what “looks like a good way to resolve problems at one scale does not hold at another scale.” “Even worse,” Harvey argued, “good solutions at one scale (say, the local) do not necessarily aggregate up, or cascade down, to make for good solutions at another scale (say, the global).”10Harvey, “Future of the Commons,” 102. We argue in chapter 4 of this volume that Ostrom brought to the analysis of human governance of CPRs a granular understanding of scale and degree. Hence, she would be the first to admit that at a given scale a solution might be no longer applicable to the problem at hand. This is ultimately why, in his opinion, “the lessons gained from the collective organization of small-scale solidarity economies along common-property lines cannot translate into global solutions without resort to nested hierarchical forms of decision making.”11Harvey, “Future of the Commons,” 102. Ostrom would have likely disagreed with Harvey’s analysis as her work exposed the overreliance on the hierarchical governance models she saw as part of the “dichotomous” schema in which the government (coercively) controls public issues and the private sector controls the market.12 Elinor Ostrom, Beyond Markets and States: Polycentric Governance of Complex Economic Systems, (Nobel Prize Lecture, December 8, 2009), 409, available at https://www.nobelprize.org/uploads/2018/06/ ostrom_lecture.pdf.

While Ostrom herself recognized that people evolve economic structures and systems that are multilayered, polycentric, subject to feedback loops, and operating at multiple scales, she rarely drew on examples involving transregional engagement or extended time lines. Our work shows, however, that, given free market institutions and government interventions that amounted to enforcement of private property rights, effective environmental remediation solutions arose spontaneously among individuals separated by continents and industries. Building on Ostrom’s emphasis on local, spontaneous, and bottom-up processes, we illustrate how environmental remediation in rapidly developing economies has often been achieved historically through the decentralized and spontaneous development of lucrative by-products out of polluting emissions and residuals. Although such cases were arguably closer to a property rights approach to environmental externalities than to the type of communal management studied by Ostrom, the waste remediation cases we present ultimately relied on voluntary and decentralized processes at the core of Ostrom’s work. Unlike the cases she discussed, however, the remediation cases we have studied required from their beginning that local activities be embedded in a broader division of labor, one that included distant markets that could absorb by-products created out of former production residuals.

Our aim in this chapter is to argue that, while critics of Ostrom might have a point in terms of the scalability of communal management solutions, spontaneous bottom-up processes have nonetheless long helped private businesses and local communities address environmental degradation issues such as air, land, and water pollution in times of rapid economic development. The success of these processes, however, required the (market) participation of economic actors located far from the local communities in question.

The specific class of solutions we address consists of solutions that involve the neutralization of polluting emissions through the development of lucrative by-products out of production or processing residuals. We first discuss past assessments of the polluting emissions problem before addressing the incentives that promoted profitable and environmentally beneficial by-product development. We then illustrate and supplement this discussion with two historical case studies from the late-nineteenth-century United States: the development of valuable by-products out of once-highly-polluting cottonseed and the reuse of petroleum-refining residuals.

As will be illustrated, unlike many of the approaches discussed in the commons literature, the solutions to local environmental problems required the development of increasingly sophisticated and geographically distant markets. We thus present a discussion of the spontaneous emergence of local pollution management through the combination of legislative, communitarian, and market-driven processes at many levels and across large geographical distances. Our conclusion illustrates that, contrary to the arguments made by many sustainable-development theorists, long-distance trade is often critical in the development of “greener” production and processing practices. Because of this, our examples fit in with, but also supplement, Ostrom’s observation that “many successful CPR institutions are rich mixtures of ‘private-like’ and ‘public-like’ solutions defying classification in a sterile dichotomy.”13Ostrom, Governing the Commons, 14.

Increasing Profitability through Pollution Reduction

Do profit-seeking activities necessarily require that processing or manufacturing companies ignore the negative externalities from their activities? Or, to the contrary, can the profit motive provide incentives to generate “eco-innovations”—innovations that have both economic and environmental benefits? Does the profit motive need to resolve into a single incentive instead of a complex matrix of feedback mechanisms that come into play at many levels in an action arena? While Ostrom would likely find cases that allow her to answer the second and third question affirmatively,14Ostrom, Governing the Commons. it is probably fair to say that most contemporary analysts share the perspective of the systems engineering researcher Milena Ristovska that markets are replete with environmental problems and failures of all kinds because of the profitability requirement faced by firms:

Continuous pressure to cut costs in a competitive market encourages companies to externalize costs as much as possible. Unless restricted by law, companies will seek to maximize their use of the natural environment as a “sink” for waste materials and they have a strong incentive to externalize some costs by exploiting the “free” services of the natural environment. Thus pollution is an inevitable by-product of an economic system in which companies seek to maximize profits and the free market dictates that companies seek to minimize costs in order to maximize profits regardless of any environmental damage that might be caused. Market failure of this kind is very common and results from the need to stay commercially competitive in the short term.15Milena Ristovska, “The Role of the Business Sector in Promoting a ‘Greener’ Future,” International Business & Economics Research Journal 9, no. 4 (2010): 21.

This perspective is largely shared by economists and other analysts who believe that firms only have an incentive to eliminate waste when benefits exceed costs and that corporate social responsibility initiatives, public pressures, and the threat of regulation might play a more significant role in this respect. While the latter has sometimes been true, much evidence does suggest that the profit motive was typically the key motivation behind the actions of creative business owners, managers, and technicians who invested in the development of new ways of doing things in the hope (often turned to reality) that value can be created out of environmental nuisances.16Pierre Desrochers, “Regional Development and Inter-industry Recycling Linkages: Some Historical Perspective,” Entrepreneurship and Regional Development 14, no. 1 (2002): 49–65; Pierre Desrochers, “Did the Invisible Hand Need a Regulatory Glove to Develop a Green Thumb? Some Historical Perspective on Market Incentives, Win-Win Innovations and the Porter Hypothesis,” Environmental and Resource Economics 41, no. 4 (2008): 519–39; Pierre Desrochers and Colleen Haight, “Squandered Profit Opportunities? Some Historical Perspective on Wasteful Industrial Behavior and the Porter Hypothesis,” Resources, Conservation and Recycling 92 (2014): 179–89; Pierre Desrochers and Samuli Leppälä, “Industrial Symbiosis: Old Wine in Recycled Bottles? Some Perspective from the History of Economic and Geographical Thought,” International Regional Science Review 33, no. 3 (2010): 338–61.

First, the value of residuals was often initially low or non-existent, while their disposal or neutralization costs (occasionally triggered by actual or potential property rights–based lawsuits) were often significant. Second, unlike domestic waste, industrial residuals were uniform in nature and typically available in large quantities. Last, they were often produced in industrialized regions, thus reducing transportation costs to different industrial plants where they could be used as inputs (needless to say, additions to existing plants were often built for that purpose). In this context, several manufacturers followed a process described by the French engineer Paul Razous at the turn of the twentieth century.17Paul Razous, Les déchets industriels: Récupération, utilisation (Paris: Dunod, 1905). Residuals were first thoroughly analysed and broken into their basic components. If any of these had significant value, it was isolated. If no component was particularly valuable on its own, the composition of the residual was compared to the composition of similar products such as fuels, fertilizers, animal food, and building materials. Two scenarios were then possible. If the residual components were similar to those of a given commercial input, the residual could probably be used for the same purpose. If one or a few components were missing, it was often possible to add whatever was necessary to turn the residual into a suitable substitute.

Perhaps the best-known historical instance of by-product development out of processing residuals occurred in the meatpacking industry. As the American editor and essayist William George Jordan remarked more than a century ago, “when an ox was slaughtered [in past decades], forty per cent of the animal was wasted.” By the late nineteenth century, however, “nothing [was] lost but its dying breath.”18William George Jordan, “Wonders of the World’s Waste,” Ladies’ Home Journal, October 1897, 8, available at https://books.google. ca/books?id=LKwiAQAAMAAJ&source=gbs_similarbooks. Among other creative developments, blood was used as an input in sugar refining and papermaking or turned into doorknobs and buttons. Bones were not only the primary material in the manufacture of countless combs, buttons, handles, and various types of jewelry, but the dust created as a result of sawing them became food for cattle and poultry. Even “the undigested food in the stomach, which formerly cost the packers of Chicago thirty thousand dollars a year to remove and destroy,” was used to make paper.

An anonymous contributor to the Illustrated Magazine of Art had suggested nearly five decades earlier than Jordan’s analysis of waste recycling that, “as the best way of destroying an enemy is to make him a friend, so the best way of getting rid of a noxious gas is to find a method by which it may be retained in a useful form.”19 “Curiosities of the Chemistry of Art,” Illustrated Magazine of Art 1, no. 6 (1853): 359, available at https://www.jstor.org/stable/20538008?seq=1#metadata_info_tab_contents. The contributor described how “the operations of chemistry have brought into employment a thousand substances which had otherwise been useless or pernicious.”20“Curiosities of the Chemistry of Art,” 358. After discussing several examples, he concluded, “Such is the economy of the chemistry of art, which, by the combination of apparently useless elements, produces, as though with the touch of an enchanter’s wand, order out of confusion, advantage and beauty from the offensive and injurious.”21“Curiosities of the Chemistry of Art,” 358.

Arguably the most important chronicler to work on this issue was the Danish-born British writer Peter Lund Simmonds (1814– 1897).22 Pierre Desrochers, “Promoting Corporate Environmental Sustainability in the Victorian Era: The Bethnal Green Museum Permanent Waste Exhibit (1875–1928),” V&A Online Journal, no. 3 (Spring 2011), http://www.vam.ac.uk/content/journals/research-journal/issue-03/promoting-corporate-environmental-sustainability-in-the-victorian-era-the-bethnal-green-museum-permanent-waste-exhibit-1875-1928/. In the thirty-five chapters of Waste Products and Underdeveloped Substances; or, Hints for Enterprise in Neglected Fields (1862), he described numerous examples of creating wealth from waste from various animal, vegetable, and mineral substances. In the conclusion of the revised edition of his book, Simmonds observed,

I . . . bring my labours to a close—not because the subject is exhausted, since every day furnishes new instances of what has become one of the most striking features of modern industry—to let nothing be lost, and to re-work with profit and advantage the residues of former manufactures— but for fear I should weary the reader with too ponderous a volume.23 Peter Lund Simmonds, Waste Products and Underdeveloped Substances; or, Hints for Enterprise in Neglected Fields, rev. ed. (London: Hardwicke and Bogue, 1876), 477..

Numerous contemporaneous writers made similar comments.24See Pierre Desrochers, “Freedom versus Coercion in Industrial Ecology: A Reply to Boons,” EconJournalWatch 9, no. 2 (2012): 78–99. For instance, in his Handbook of Chemical Technology, German professor of chemistry Johann Rudolf von Wagner wrote that the “ideal of a chemical manufactory is that there should be no real waste products at all, but only chief or main, and by-products. The better, therefore the waste products are applied to good and advantageous use, the more nearly the manufactory will approach the ideal, and the larger will be the profit.”25 Johann Rudolf von Wagner, Handbook of Chemical Technology, translated and edited from the eight German edition by William Crookes. (New York: D. Appleton and Company, 1872), 3. In 1886, an encyclopedia entry described how “in the earlier days” of many manufacturing branches, “certain portions of the materials used have been cast aside as ‘waste,’” but over time “first in one branch and then in another, this ‘waste’ material has been experimented upon with a view to finding some profitable use for it; and in most instances the experiments have had a more or less satisfactory results.”26Hazell’s Annual Cyclopædia, ed. E. D. Price (London: Hazell, Watson, and Viney, 1886), s.v. “The Utilisation of ‘Waste Materials,’” available at https://books.google.ca/books?id=dv0BAAAAYAAJ&pg=PA462&source=gbs_toc_r&cad=3#v=onepage&q&f=false. A year later, a scientific retrospective highlighted “the utilization of waste materials and by-products” as a “leading feature of the Victorian epoch.”27“Her Majesty’s Jubilee: A Scientific Retrospect,” Chemical News 55, no. 1440 (1887): 299, available at http://books.google.ca/ books?id=cJwEAAAAYAAJ.

Writing at the turn of the twentieth century, the American technical writer Leebert Lloyd Lamborn commented that if “there is one aspect more than any other that characterizes modern commercial and industrial development,” it is “the utilization of substances which in a primitive stage of development of any industry were looked upon as worthless.” These were either “secondary products incurred in the manufacture of the main commodity, for which the industrial acumen of the age found no use,” or else products for which, “if a use were known, the prejudices and conservatism of society allowed them to languish in the shadow of a similar commodity already strongly intrenched.”28Leebert Lloyd Lamborn, Cottonseed Products: A Manual of the Treatment of Cottonseed for Its Products and Their Utilization in the Arts (New York: D. Van Nostrand, 1904), 16, available at https:// archive.org/details/cottonseedprodu00lambgoog/page/n13.

Although these analysts sometimes mentioned social, environmental, and (property rights–driven) legal concerns, most of them suggested that the profit motive was the main incentive behind widespread by-product development. Among these was Simmonds, who argued that as “competition becomes sharper, manufacturers have to look more closely to those items which may make the slight difference between profit and loss, and convert useless products into those possessed of commercial value.”29Quoted in Bethnal Green Branch of the South Kensington Museum, Descriptive Catalogue of the Collection Illustrating the Utilization of Waste Products (G.E. Eyre and W. Spottiswoode, 1875), 4. Even Karl Marx agreed with the notion that waste recovery increases “the rate of profit” because it helps “reduce the cost of the raw material to the extent that [materials recovered from waste] are saleable.” After production efficiencies from economies of scale, he viewed industrial waste recovery as “the second great branch of economy in the conditions of production.”30Karl Marx, Capital, vol. 3, The Process of Capitalist Production as a Whole, trans. (1894; repr., Chicago: Charles H. Kerr, 1909), available at http://www.econlib.org/library/YPDBooks/Marx/mrxCpC. html. More than a century ago the editor of the Boston Journal of Commerce, Henry J. Kittredge, similarly commented,

Nothing in the arts of manufacture is more indicative of economic efficiencies than the utilization of products that have been rejected as wastes or residues in the industrial processes. . . . The refuse of to-day is a source of profit tomorrow; and this has been going on for years and probably will be going on for years to come. . . .

New revelations and new uses are constantly being found for substances of all kinds, whether in their original forms, or in their changed forms due to outside agencies. The world’s increment of wealth is largely dependent upon finding new and more economical uses for materials, however exalted or humble they may be in the industrial scale.31Henry G. Kittredge, “The Utilization of Wastes and By-Products in Manufactures with Special Reference to the Decade of 1890– 1900,” U.S. Census Bulletin, no. 190 (June 16, 1902), 3, available at https://www2.census.gov/prod2/decennial/documents/ 03322287no164-208ch4.pdf.

Two North American Case Studies of How Companies Turned Polluting Waste into Wealth

We will now use two historical case studies to illustrate in more detail the processes of by-product development and its incidental environmental benefits, showing the spontaneous emergence of solutions ameliorated across different industries and in different settings.

Cottonseed By-Products

Cotton is the world’s most significant and most industrialized textile crop. Gossypium hirsutum, also known as upland or short-staple cotton, typically accounts for between 90 and 96 percent of world cotton production. Gossypium barbadense, also known as Egyptian, sea-island, long-staple, or pima cotton, is the second most valuable variety, accounting for between 1 and 6 percent of world cotton production. While pima cotton fibers are strong, long, and fine, and hence ideal for superior products, the variety’s yield and resistance to pests and diseases are inferior, making the species less economically advantageous.32This section borrows from Pierre Desrochers and Joanna Szurmak, “Long Distance Trade, Locational Dynamics and By-Product Development: Insights from the History of the American Cottonseed Industry,” Sustainability 9, no. 4, art. 579 (2017), https://www.mdpi. com/2071-1050/9/4/579. See that text for additional source material and technical discussions.

The cotton fruit is known as a boll; each boll contains three to five loculi or compartments in which five to eleven seeds mature. The boll opens halfway through its approximately one-hundredday growth cycle, allowing the fiber, known as lint, to dry. Seeds are 66 percent of the weight of a measure of seed cotton (cotton boll with seeds and lint); they are characterized by a dark brown or ash-colored husk which, particularly in the upland cotton species, is entirely encased in short, compact white fuzz commonly called linters. Pima cottonseed husks, much less fuzzy than their upland relatives, appear black and smooth instead of dark brown and rough.

Both upland and pima cotton were cultivated in the United States by the eighteenth century. Until the development and widespread use of the cotton gin in the mid-1790s, the limited volume of cottonseed available in the United States was either replanted (about 10 percent of the total), fed to mature ruminants that could digest the seed,33For a short discussion of cottonseed as a feed for ruminants, see Lawton Stewart and Johnny Rossi, “Using Cotton Byproducts in Beef Cattle Diets” (Bulletin 1311, University of Georgia Cooperative Extension, 2010), http://cotton.tamu.edu/General%20Production/ Georgia%20Cotton%20Byproducts%20for%20Beef%20Cattle%20 B%201311_2.pdf. or used as fertilizer once the seeds had been deactivated by fermenting them in compost heaps, keeping them wet in large piles, or covering them in deep furrows. After the advent of the cotton gin and the sudden dramatic increase in the profitability of the cotton crop, however, the land area devoted to cotton soon increased dramatically. As more cotton was grown and harvested, large heaps of cottonseed proved an unmitigated nuisance.

While the seeds could be burned, cottonseed fires were difficult to control because of dangerously flammable oil and linters. Another complaint was that “land where piles of seed had remained for some time refused to bring forth any plants at all.”34Eugene Clyde Brooks, The Story of Cotton and the Development of the Cotton States (Chicago: Rand McNally, 1911), 354, available at https://archive.org/details/storyofcottondev00broouoft/page/i. Since cottonseed contains a toxic substance called gossypol, it proved lethal as a feed for most livestock, prompting some farmers to isolate their animals from the harmful seeds. Thus, cottonseeds were often put in pens in “order to protect the hogs, . . . and both cattle and hogs were carefully guarded to see that they did not feed on them.”35Brooks, Story of Cotton, 353. Similar concerns about harming livestock were raised when cottonseed hulls were proposed as animal feed, although the burning of hulls for fuel provided an early, if insufficient, outlet for this residual product. One seemingly widespread disposal method was to dump cottonseeds in flowing streams and let them be washed away,36Luther A. Ransom, The Great Cottonseed Industry of the South (New York: Oil, Paint and Drug Reporter, 1911), available at https://archive.org/details/greatcottonseedi00ransrich/page/n4. creating large-scale pollution of a CPR. Most planters, however, elected to “dump them into creeks or swamps where the cattle and hogs could not find them,”37Brooks, Story of Cotton, 353. but the result was “a miasmic stench which was not only very offensive, but was thought to produce malaria and other diseases.”38Brooks, 353.

Interestingly, in the early years of the crop’s rapid expansion, the problem of cottonseed disposal was so significant that some commentators seriously suggested “that it would be better . . . to discontinue the production of cotton, since the seed were injurious to man, beast, and plant.”39Brooks, Story of Cotton, 354. Some of America’s earliest environmental regulations can be traced back to cottonseed disposal. For instance, similarly to the codes of Alabama and Georgia, the Revised Code of Mississippi of 1857 included a significant fine for “throw[ing] or permit[ting] to be thrown the cottonseed from [any cotton gin] into any river, creek, or other stream of water which may be used by the inhabitants for drinking or fishing therein.”40Rev. Code of the Statute Laws of the State of Miss. (1857), art. 19. It also contained a provision that prevented ginners from accumulating seed within half a mile of a city, town, or village so as to “not prejudice the health of the inhabitants.”41Rev. Code of the Statute Laws of the State of Miss., art. 18. We see, thus, an example of state regulation of a rapidly evolving negative agricultural and crop-processing externality.

For the first five decades of the nineteenth century, many innovators tried in vain to create wealth out of the oily and fibrous, yet hazardous, waste that was cottonseed. One problem was the poor fit of existing oil extraction technology to the unique challenges of cottonseed. Most entrepreneurs’ reliance on simple oil extraction techniques was vexed by the capacity of upland cottonseed linters to absorb a significant portion of the extracted oil. Other issues with cottonseed use for oil included the abundance and cheapness of competing goods—animal fats and oils in the American market—as well as the consumer prejudice against vegetable oils. Because of its composition, cottonseed oil also proved inadequate for a number of industrial uses, for instance as a lubricant, a wood filler, a leather-treating agent, and a component in paint. In time, however, numerous lucrative uses were developed.42 Desrochers and Szurmak, “Long Distance Trade.” As the physician and one of the first analysts of the cottonseed industry, Henry Ogden, put it nearly a century and a half ago, while creating value out of cottonseed was “a discovery of no slight magnitude and importance,” it came “as most great discoveries do, accompanied by pecuniary loss, delay and disappointment; and [the industry] was successfully established only after repeated failures.”43Henry V. Ogden, Paper on Cotton-Seed Oil and Cotton-Seed Oil Mills (Atlanta: Constitution Print, 1880), available at https://archive. org/details/paperoncottonsee00ogderich/page/n4.

Writing in 1889, the engineer and author Robert Grimshaw observed that cottonseed was long “considered a refuse for which there was no use; long burned or thrown away,” but that “its main and by-products are now very important elements in our national industries. The garbage of 1800 became the fertilizer of 1870, the cattle food of 1880, and is now made to yield table food and useful articles of industrial pursuits.” The oil, “more widely known throughout the world and used for a greater variety of purposes than any other oil,” was by then most valuable, but the “residuum after [cottonseed oil’s]expression” was a valuable fertilizer and the “best cattle food”; the ashes of the hulls delivered “potash of high commercial value”; and the refuse from the refining of crude oil provided a “most excellent stock for laundry and toilet soaps.”44Robert Grimshaw, “Industrial Applications of Cottonseed Oil,” Journal of the Franklin Institute 127, no. 3 (1889): 191–92. The only industry where cottonseed oil underperformed was that of illumination. Cottonseed oil pioneers had originally set their eyes on the whale oil market, but by the early 1860s petroleum-derived kerosene proved too formidable a competitor, itself in time eclipsed by electric lighting.

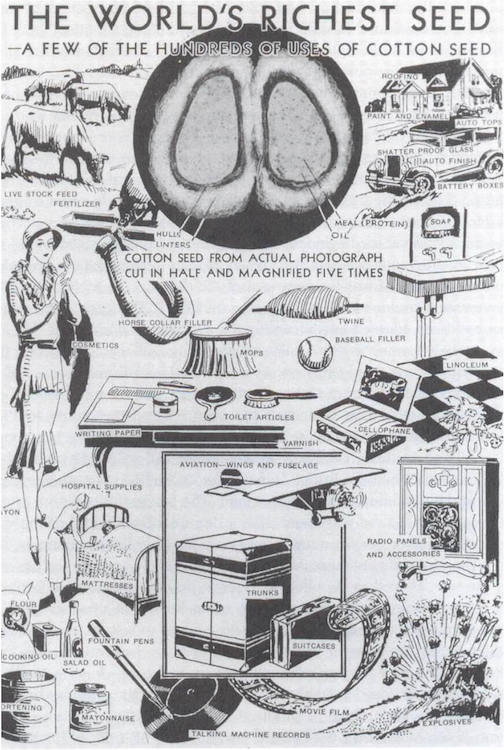

By the 1880s, Luther A. Ransom, an industrialist and former president of the Interstate Cottonseed Crushers’ Association, described cottonseed by-product development as the story “of a raw material practically without value” that, within two decades, was converted “into products worth one hundred million dollars” that brought much economic prosperity in regions desperate for it.45Ransom, Great Cottonseed Industry, 9–10. The seeds had made possible the creation of “edible oil without olives; medicinal oil without codfish; butter without cows; ice cream without cream; lard without hogs; fertilizers without blood; mattresses without hair; stock feed without corn or oats and explosives without powder,” the result being “as good or better articles than the originals.”46Ransom, 53. These and later advances are perhaps conveyed most effectively in a 1930 promotional poster produced by the National Cottonseed Products Association and titled “The World’s Richest Seed” (see figure 1).

Figure 1. 1930 Promotional Poster, “The World’s Richest Seed”

Source: Produced by the National Cottonseed Products Association. (Image reproduced with the permission of the National Cotton Council of America.)

Beginning in the middle of the twentieth century, however, palm-seed oil, soybeans, petroleum by-products, and other alternatives progressively displaced cottonseed and ushered in a decline in the percentage of American cottonseed sent to crushing mills, from a high of nearly 90 percent in 1950 to approximately 45 percent in 2000. Whole cottonseed was not wasted, though: despite being a rather inconvenient feedstuff to handle, it was increasingly added to the diet of certain livestock, primarily lactating dairy cows and beef cattle, a practice once frowned upon. In other words, while the uses of cottonseed might not be as numerous as they once were, market actors have nevertheless found ways to create value out of what would otherwise be an environmental problem.47Desrochers and Szurmak, “Long Distance Trade.”

Petroleum By-Products

Even greater creativity and market complexity can be observed in the history of the petroleum production and refining industries.48For additional details about the early days of by-product development, see Harold F. Williamson and Arnold R. Daum, The American Petroleum Industry: The Age of Illumination, 1859–1899 (Evanston, IL: Northwestern University Press, 1959), chapter 10. Petroleum was first sought after in western Pennsylvania in the 1850s, as it proved a more economical source of kerosene (a combustible hydrocarbon used for illumination), which had previously been produced from coal, oil shale, and bitumen. Kerosene was seen as a superior and more reliable alternative to animal and vegetable oils, the best of which were derived from sperm whales.49Dominick T. Armentano, “The Petroleum Industry: A Historical Study in Power,” Cato Journal 1, no. 1 (1981): 53–85; Brian Black, “Oil Creek as Industrial Apparatus: Re-creating the Industrial Process through the Landscape of Pennsylvania’s Oil Boom,” Environmental History 3, no. 2 (1998): 210–29; Brian Black, Petrolia: The Landscape of America’s First Oil Boom (Baltimore: Johns Hopkins University Press, 2000). In the early days of the industry much of the raw material was wasted during extraction, storage, and transport. As one traveler reported in 1864,

At the curves of the bluffs, sometimes at their feet, but more frequently on the opposite sides of the creeks, wide flats extend. These flats for miles are covered with black derricks. . . . The whole aspect is as unattractive as any one with a prejudice for cleanliness, a nose for sweet smells, and a taste for the green of country landscapes can well imagine. Every thing you see is black. The soil is black, being saturated with waste petroleum. The engine-houses, pumps and tanks are black, with the smoke and soot of the coal-fires which raise the steam to drive the wells. The shanties—for there is scarcely a house in the whole seven miles of oil territory along the creek—are black.50B. Franklin, “After Petroleum,” Harper’s New Monthly Magazine 30 (1864): 59.

Historical accounts, however, suggest that such environmental damage was then largely deemed an acceptable price to pay for the wealth generated by the industry.51Franklin, “After Petroleum.”

Nevertheless, problems related to the extraction, handling, transportation, and storage of crude oil were soon addressed through advances such as greater recovery at the pump, the development of better barrels (eventually metal drums), and the building of pipelines (at first made out of wood) and railroads (including the development of metal tank cars), among others. The residual matter left after the distillation of petroleum for the extraction of valuable raw materials, however, remained problematic. As the geographers Robert C. Estall and R. Ogilvie later commented, despite the very high quality of Pennsylvania crude oil, these leftover portions “were waste products, and the main problem was how to dispose of them.”52Robert C. Estall and R. Ogilvie Buchanan, Industrial Activity and Economic Geography: A Study of the Forces Behind the Geographical Location of Productive Activity in Manufacturing Industry, 3rd rev. ed. (London, UK: Hutchinson, 1973), 221. Petroleum waste disposal typically occurred through dumping or burning, and either way affected the local environment.

By-product development once again allowed wealth to be created out of polluting residuals. In the first quarter of a century after the petroleum industry began, the proportion of waste was reduced from about half of the original material to less than a quarter. The mid-1860s thus saw the creation of lubricating oils, greases, paraffin, petrolatum (or petroleum jelly, better known by the trademark Vaseline), candles, insect repellents, and solvents out of the liquid residue. These new commodities, however, were largely extracted from the “middle of the barrel.” By contrast, lighter gasoline and most heavy residuals remained problematic, save for the use of some heavy crude oil and residuum as fuels in refining operations and in buildings in oil-producing regions when alternative fuels (typically coal) were more expensive. As the refining specialist William Leffler put it, “Gasoline and naphtha were mostly considered waste products, often allowed to ‘weather,’ a euphemism for evaporating into the atmosphere, before the kerosene was recovered. Sometimes refiners just burned the light material in pits or dumped it into nearby streams to get rid of it,” much as cotton ginners did with cottonseed.53William L. Leffler, Petroleum Refining in Nontechnical Language, 4th ed. (Tulsa, OK: PennWell, 2008), 1. Innovation scholars Newton Copp and Andrew Zanella wrote, somewhat more bluntly, “The typical solution for this problem was to dump the gasoline into adjacent rivers and hope it would evaporate before the river caught on fire!”54Newton Copp and Andrew Zanella, Discovery, Innovation and Risk (Cambridge, MA: MIT Press, 1993), 147. The problem was that, while gasoline found limited markets by being used in products such as solvents for paint and varnish, it proved too flammable and too volatile to be used for household lighting and heating. Similarly, while some of the heavier components of crude oil had limited uses for road surfacing and roofing, no adequate furnace technology had been developed to burn heavy oil for space heating.

By the mid-1870s, Standard Oil employees began selling paraffin wax for chewing gum and residual oil tar and asphalt for road building. They soon added lubricants (for railroads and machine shops), candles, paints, dyes, and industrial acid. In 1880, Standard Oil acquired the Chesebrough Manufacturing Company of New Jersey in order to strengthen its sales of petroleum jelly.55Ron Chernow, Titan: The Life of John D. Rockefeller, Jr. (New York: Random House, 1998), 181. By the end of the nineteenth century, the company sold approximately two hundred petroleum by-products, including “naphtas for local anesthetics, solvents for industry, fuel for stoves and the internal combustion engines, wax for pharmaceuticals and candles, oils and lubricants to free machines from friction, heavy oils for the gas industry.”56Copp and Zanella, Discovery, Innovation and Risk, 156.

In his 1908 book Wealth from Waste, George Powell Perry attributed much of the success of the Standard Oil corporation to the “wise use of that which was once regarded worthless” rather than to “financial shenanigans and deceptive practices.” He supported his contention using a brief account of the development of paraffin out of a “sticky, slimy stuff . . . left over from the refining business”:

At first [the residual] was thrown into the river. But soon the authorities complained because of the pollution it produced. Then it was put into a deep trench and they tried to burn it. It made such a furious flame that the heat became unendurable and the strongest wall could not resist it. In great perplexity the company finally sought the help of some expert chemists to see if some way could not be found to get rid of the nuisance. It was at that time that a process was discovered whereby this disagreeable refuse could be converted into paraffine. Then it was found that this troublesome refuse could be made a good source of revenue.57George Powell Perry, Wealth from Waste or Gathering Up the Fragments, 2nd ed. (New York: Fleming H. Revell, 1908), 73–74.

A few illustrations can illuminate how by-products relieved pressures on flora and fauna. For instance, paraffin was first introduced into the pharmaceutical industry as a substitute for wax, spermaceti (the highest grade of whale oil), almond oil, and lard in cerates and salves.58Williamson and Daum, American Petroleum Industry, 249. By 1870 it had supplanted spermaceti as the main laundry sizing for both domestic and commercial uses while gaining market shares in textile manufacturing, being used as a wood preservative, and displacing natural rubber for waterproofing tents, boots, and coats.59Williamson and Daum, 250. Each product that petroleum waste supplanted allowed animal and plant species to be spared, exerting less pressure on the environment in two interconnected ways: by reusing environmental pollutants and by reducing the harvesting of living species as resources. Once again, as with the development of cottonseed by-products, a number of polycentric efforts by independent producers, innovators, and tinkerers, often initially not affiliated with broader commercial interests, managed to develop the critical mass of failed prototypes from which more successful and, in the case of Standard Oil, more coordinated efforts could emerge.

In his early twentieth-century history and economic analysis of Rockefeller’s founding and leadership of Standard Oil, Gilbert Holland Montague wrote that the main complaint voiced by the company’s competitors was that the new “improved methods of utilizing by-products” had made these by-products “as remunerative as the refined oil itself,” which gave the company a significant competitive advantage. As was widely understood at the time, the main challenge of by-product development was that it required “the greatest specialization of methods, encouragement of invention, investment of capital, and extension of plant,” a combination of efforts beyond the capacity of smaller refining operations. In the end, Montague concluded that the large profits Standard Oil derived from by-products was “owing entirely to its superior mechanical efficiency and organization.”60Gilbert Holland Montague, “The Later History of the Standard Oil Company,” Quarterly Journal of Economics 17, no. 2 (1903): 323–24, available at https://doi.org/10.2307/1883667.

The advent of electric lighting in the late nineteenth century turned kerosene into a by-product of gasoline refining. Writing in 1920, the journalist Frederick A. Talbot observed, somewhat carelessly but colorfully, that the development of the internal combustion engine ensured that the volatile spirit which hitherto had been spurned and burned wastefully by the refineries was immediately discovered to be invested with a value which had heretofore escaped attention. It formed the ideal fuel for the new motor. Forthwith wanton destruction of the volatile spirit was abandoned. Every drop was carefully collected, and, as time went on and the demand for the light liquid fuel increased, the refiners put forth great effort to wring every possible dram of [gasoline] from the crude petroleum.61Frederick Arthur Ambrose Talbot, Millions from Waste (Philadelphia, PA: J.B. Lippincott Company, 1920), 16–17.

Talbot also commented that “forty years ago the boring of [an oil] well was followed with mixed feelings,” because a successful strike would unavoidably “crash through the roof of an underground reservoir of petroleum gas” that might then blow up and cost the lives of the crew. “Ignorant of the value of this product, though painfully aware of its danger,” Talbot wrote, “the early seekers for oil led this gas through a pipe to a point some distance away” where it was ignited and “allowed to burn merrily in the open air.” It was only when “the flame flickered and expired” that the “boring for the precious liquid” would proceed. In time, however, the flaring of natural gas was recognized for what it was: the waste of a valuable resource. As Talbot observed, “with passing years and progress came enlightenment. The gas is no longer wasted; it is trapped. In some instances, it is led through piping for hundreds of miles to feed hungry furnaces engaged in the making of steel and other products.”62Talbot, Millions from Waste, 15–16. This passage illustrates the positive feedback loops that spontaneously arose to take advantage of the versatility and potency of petroleum by-products.

In time, diesel became the dominant fuel for ships, locomotives, and heavy-duty vehicles such as buses and trucks, while the development of jet and turbo-jet aircraft eventually provided a new large-scale market for kerosene.63Needless to say, large ships are also powered by bunker fuels. To mention but one later instance of by-product development, the boom in plastics production can be traced back to the development of the cracking of crude oil to produce high-quality gasoline, a process that generated residual gases that were first burned as waste, but that eventually became a cheap feedstock for the production of polymers.64Frans Lox, Packaging and Ecology (Leatherhead, UK: Pira International, 1992).

After writing that more than five thousand different products had been developed from crude oil, the geographer Joseph Russell Smith and his collaborators observed in 1961, “The meat-packing industry has long boasted that it uses all parts of a pig except the squeal. The petroleum industry sometimes adds the odor of oil to odorless gas to help detect leaks in pipelines. The petroleum industry claims that it uses everything in crude oil, including the smell.”65Joseph Russell Smith, M. Ogden Phillips, and Thomas R. Smith, Industrial and Commercial Geography, 4th ed. (New York: Holt, Rinehart and Winston, 1961), 309.

Long-Distance Trade and Win-Win Innovations

The successful by-product development in the cotton and petroleum industries described in the previous section would have never taken place without a division of labor and markets that went much beyond the local scale. This section will discuss and illustrate these prerequisites in more detail.

Petroleum Markets and Refining Operations

As discussed earlier, in time the interplay between the pursuit of economic self-interest and broader community and environmental interests resulted in improved production technologies and by-product development that neutralized problems at the source. From the beginning in the second half of the nineteenth century these solutions relied on a broader division of labor and long-distance trade, both in terms of final markets66The European market from the mid-1860s onward for several years absorbed approximately 70 percent of the refined crude from the United States. Kim Leonard, “Oil Boom: Pittsburgh Was Nation’s First Petroleum Capital,” Trib Live, October 4, 2009, https://archive. triblive.com/news/oil-boom-pittsburgh-was-nations-first-petroleum-capital/. and of more distant location of processing operations. For instance, in the 1860s and 1870s refining activities relocated from production sites in western Pennsylvania to larger metropolitan centers such as Pittsburgh, Cleveland, Philadelphia, and New York. The rationale behind these moves included the high cost of refining near pumping sites because of heavy charges there for shipping machinery and inputs (e.g., sulfuric acid), along with the high value of local land. A location like Pittsburgh, by contrast, provided access to well-developed transportation networks both by land and by water, along with a cheap supply of coal, labor, and other inputs.67Armentano, “Petroleum Industry.”

Business historians Ralph and Muriel Hidy explain the location of refineries from the 1860s to the turn of the twentieth century: “Proximity to producing wells was a factor but not the primary one. Transportation costs on finished products to markets as well as on supplies to refineries were important considerations. The location of markets, therefore, assumed primary significance.” Key factors thus included the “availability of fuel and labor, ground space for expansion of the plant, water supply, taxes, state and municipal regulatory provisions, and available fire protection.”68Ralph W. Hidy and Muriel E. Hidy, History of the Standard Oil Company (New Jersey): Pioneering in Big Business, 1882–1911 (New York: Harper & Brothers, 1955), 417–18. Another consideration for large and expensive operations was keeping an eye on “continuous changes in sources of supply and rapid exhaustion of producing areas” that favored the potential staying powers of oil fields and room for expansion of existing operations. In time, too, the emergence of significant new production areas near growing markets pulled some refining operations toward them. In the end, if there were “two chief determinants in selecting the exact spot for a refinery, they were the location of the market and available facilities for transporting finished products.”69Hidy and Hidy, History of the Standard Oil Company, 419.

Needless to say, the location of profitable refineries since these early days has remained dependent on the access to feedstocks and the ability to distribute refined products. As the Deutsche Bank research analyst Lucas Herrmann and his coauthors observed, apart from configuration and crude supply, “location is probably the third most important determinant of a refinery’s ability to capture profit” because it ultimately determines likely competition and affects crude freight and product dispatch costs, as well as other factors such as labor and environmental regulation compliance costs.70Lucas Herrmann, Elaine Dunphy, and Jonathan Copus, Oil and Gas for Beginners: A Guide to the Oil & Gas Industry (London: Deutsche Bank AG, 2010), 164. In terms of geography and logistics, petroleum refineries have often been classified on the basis of their proximity to resources, markets, or transit points, such as, for instance,

- Resource refineries. Located near and supplied from local deposits, resource refineries deliver products locally and elsewhere. Export-oriented refineries typically face higher construction and refined product transportation costs than other refineries.

- Seaboard export refineries. Supplied from local or distant oilfields, seaboard export refineries deliver refined products to local and distant markets. Easy access to water and shipping routes minimizes transport and logistical costs, in terms of both imports and exports.

- Market refineries. Market refineries are located in regions without significant oil resources but with important local markets. They are supplied from distant crude oil deposits and have little incentive or capability to sell beyond the local market.71 Robert B. McNee, “Functional Geography of the Firm, with an Illustrative Case Study from the Petroleum Industry,” Economic Geography 34, no. 4 (1958): 321–37.Another factor that historically has explained the further development or persistence of some refineries was the building of adjacent and symbiotic petrochemical complexes that depend on large and constant supplies of bulky refinery materials that do not travel well (e.g., naphtha), but that could also profitably supply various essential inputs to refining operations.Refinery complexity and the state of transportation at any given time have thus typically trumped geographical proximity to production sites. In other words, the fact that a particular crude oil was (or is) pumped out of the ground in relatively close proximity to a refinery might be of no practical consequence if the crude oil cannot be delivered to the refinery because of a lack of infrastructure connecting it to the oil wells, the refinery is not equipped to handle the type of crude oil produced, or the refinery cannot profitably deliver its refined products to suitable markets.

Refinery location dynamics changed over time as a result of new supply sources, improved refining and transportation technologies (that often mandated increased economies of scale), and growing or declining markets. For instance, in post–World War II Europe, seaports were the logical locations for refineries that depended on overseas crude oil, and from there refined products could be conveniently conveyed to inland customers. As inland markets grew and became more diversified, however, crude oil was increasingly moved by pipelines to new inland refineries while coastal refineries became more oriented toward local and spot markets (to balance overall supply and demand in other regions).72Willem Molle and Egbert Wever, “Oil Refineries and Petrochemical Industries in Europe,” GeoJournal 9, no. 4 (1984): 421–30. The same processes have since been playing out on a worldwide scale.

The locational dynamics of refining operations have also shown a few recurring patterns over time. For instance, because moving crude oil is always cheaper than moving a similar volume of different refined products,73Apart from logistical complications, refined petroleum products require either dedicated or “clean” tanks for shipping, and either lose value or require further processing when they are sent in batches through pipelines. there is (1) a more direct correlation between the refinery-and places where refined goods are sold to consumers in terms of transportation costs than between oil wells and refineries, and (2) a more limited area for refined products than for crude oils. Other considerations, however, such as the fact that the molecular composition of available crude oils often makes it economically impossible to perfectly match refinery output and consumer demand, will always create the need for inter-regional trade in refined petroleum products.

Another pattern in the locational dynamics of refining is the relaxation of locational constraints on the production of niche specialty products. Finally, any technological advance or infrastructure development that makes it more convenient or cheaper to ship refined petroleum products and refining operation inputs relaxes the geographical constraints that benefit market refineries. Although some landlocked refineries have fewer options, they can be very profitable because of (quasi)regional monopolies and sudden increases in local crude oil production that lower crude oil prices. When there are opportunities to take advantage of significant price differences between two or more markets (what economists refer to as arbitrage), creative businesspeople tend to find a way around logistical bottlenecks.

In the end, while some landlocked refineries that rely on fewer crude oil options have proved very profitable because of regional monopolies,74Andrew Inkpen and Michael H. Moffett, The Global Oil and Gas Industry: Management, Strategy and Finance (Tulsa, OK: PennWell, 2011), 455. in most cases the most profitable—and therefore the more efficient—creation of refined petroleum products has long required long-distance trade in terms of both feedstock and refined products.

Cottonseed Markets and Processing Operations

As with petroleum refining, the development of by-products out of cottonseed involved numerous steps through which a complex raw material was broken down into components that were often (re)combined with other materials.75This section borrows from Desrochers and Szurmak, “Long Distance Trade.” See that text for additional source material and technical discussions. Because of the insufficient size of the market and the initial reluctance of domestic consumers, finding profitable markets for cottonseed further implied moving large quantities of material over long distances. The result, in the words of Wiliam C. Mullendore, an economics education promoter and president of California utility companies, was that “cottonseed must go through an unusually large number of steps in its passage from the producer to the consumer” and that “each step of manufacture and distribution represents a separate and distinct phase of the industry, in many instances as to both location and ownership.”76W. C. Mullendore, History of the United States Food Administration, 1917–1919 (Palo Alto, CA: Stanford University Press, 1941), 282. Most of these steps or phases arose spontaneously in response to demand, opportunity, and profitability—as Ostromian ground-up interactions, not planned interventions.

From its early days, the cottonseed value chain was built around the interactions between numerous market actors that were often physically distant from each other:

- Cotton producers (both large ones that employed seasonal cotton pickers or tenant farmers and smaller, independent ones) produced field cotton and might have historically taken a portion of cottonseed back home. Producers had the option to use the seeds for planting, to sell them to an intermediary, or to sell them directly to a cottonseed oil mill.

- Ginners separated the fiber from the cottonseed. They acted as intermediaries between cotton producers and cottonseed processors.

- Cottonseed buyers, also known as dealers, brokers, or wholesalers, traded in cottonseed.

- Crushing mill operators, also known as cottonseed oil mill operators, collected and stored cottonseed, then produced crude cottonseed oil, protein-rich cottonseed cake and meal made from the pressed seed meat remaining in the press after oil extraction, and finally, empty seed hulls, as well as linters, the latter shaved from the seeds before the crushing process.

- Refiners refined the crude oil and often created other by-products in the process.

- Manufacturers of cottonseed products (including livestock feed and a wide range of consumer and industrial products) derived their products wholly or partly from the output of crushing mills and oil refineries.

- Wholesalers distributed finished products to consumer retail outlets or industrial customers.From the origins of the American cottonseed value chain in the relatively small-scale shipments of pima cottonseed cake from the US Atlantic coast to British mills, distant markets proved extremely significant in its development. In an age when unpaved land transportation was at best slow, ineffective, and extremely costly— prominent American geographer George Deasy described the roads of the time as being “little more than trails”77George F. Deasy, “Geography of the United States Cottonseed Oil Industry,” Economic Geography 17, no. 4 (1941): 348.—and warehouses lacked climate control machinery, much of the movement of cottonseed between plantations, ginning operations, and crushing operations first proceeded along waterways, especially around the Mississippi River and its navigable tributaries. It proved profitable only over relatively short distances because of the perishability of the cottonseed. Herman Nixon, an American political scientist, thus observed that, for a couple of decades after the industry took off, cottonseed-oil operations “hug[ged] the lines or points of water transportation” and the mills were concentrated in locations such as New Orleans; Memphis and Nashville, Tennessee; Natchez, Mississippi; Savannah, Georgia; and Charleston, South Carolina.78H. C. Nixon, “The Rise of the American Cottonseed Oil Industry,” Journal of Political Economy 38, no. 1 (1930): 81.

Some early processing operations, however, were located far from cotton fields because their owners had first gained experience with crushing materials such as flaxseed (before gradually moving away from those materials), and had taken advantage of the transportation routes of the time. As the American educator and author Lynette Wrenn observed, “For several decades flax cultivation had been declining in the United States because of the widespread availability of inexpensive, easy-to-clean cotton textiles. Linseed-oil mills began to experiment with various oil seeds in their search for additional raw materials.”79Lynette Boney Wrenn, Cinderella of the New South: A History of the Cottonseed Industry, 1855–1955 (Knoxville, TN: University of Tennessee Press, 1995), 8. Once the extant oil mills could be retrofitted with efficient hullers to handle upland cottonseed, little stood in the way of retooling an oilseed mill for cottonseed processing. Notably, shifting processing from one type of seed to another took ample advantage of other industrial links established for the trade in flax, sesame, or castor bean oil, such as warehousing logistics, mill workforce contracting, by-product sales, and the all-important transportation to and from the mills via the waterways. For instance, in New Orleans the entrepreneur A. A. Maginnis switched from manufacturing linseed oil (from flaxseed) to cottonseed crushing in 1856, and a St. Louis producer of linseed and castor oils followed suit the next year. In short order, in western Ohio, the center of flax growing up to that time, linseed-oil manufacturers bought cottonseed and had it shipped up the Mississippi and Ohio Rivers in boats that had previously carried goods from Cincinnati to southern ports and plantations. Flaxseed mills in the areas of New York City and Providence, Rhode Island, also switched to cottonseed processing and oil refining at the time, because they could similarly benefit from reasonable freight rates on ships returning from southern ports. In time though, most northern operations either closed or relocated closer to their main input.80Wrenn, Cinderella of the New South, 8–9.

As might be expected, much valuable material was left to rot far from navigable waterways. Henry Ogden thus insisted at the time that the claim that there was a large surplus of cottonseed available for processing was “true in the abstract [but] false in the concrete” because the surplus owed its existence to “the lack of transportation facilities and their unequal distribution over the broad area of cotton culture.” He was nonetheless confident that “sooner or later this difficulty [would] be remedied [when] the South [became] netted and fretted with railroads” and that, when this was the case, “every tonne of surplus seed will be utilized and help to swell the tide of general prosperity.”81Ogden, Paper on Cotton-Seed Oil, 12.

In time the railroad came and new cottonseed mills were built at railroad centers in order to gather cottonseed from a wider area served by the new communications network. Interestingly, Eugene Brooks, the director of the American Correspondents’ School of Textiles, observed that in the early years of the industry “river cotton seed produces a little more oil than railroad seed, and there is often a corresponding difference in their values.”82Brooks, Cotton: Its Uses, Varieties, Fibre Structure, Cultivation, and Preparation for the Market and as an Article of Commerce (New York: Spon & Chamberlain, 1898), 312. He added that while seed could be shipped by rail in bulk, bags were required for river shipping, which added to the costs of this mode of transportation.

The financial arrangements between cotton growers and ginners varied over time. Luther A. Ransom observed that in the early stages of the industry the mill operator would return “to the farmer the products of his seed, after deducting an amount sufficient to cover the cost of production and a reasonable profit.”8 83Ransom, Great Cottonseed Industry, 23.Three decades later, Deasy wrote that cotton producers would usually get bales of lint back upon the completion of ginning operations to dispose of as they wished, while the bulk of the seed was bought on the premises by the ginner. Seed would then be purchased from many other small operations, gathered until one or more railroad cars were filled, and shipped in bulk to crushing mills. From there crude oil was barreled and shipped to more distant refineries.84Deasy, “Geography of the United States Cottonseed Oil Industry.”

In the early twentieth century demand for cottonseed was sufficiently strong that, for a time, “many small mills [were] erected near the cotton fields, and these [got] their seed from the neighboring producers.”85Albert Galloway Keller and Avard Longley Bishop, Commercial and Industrial Geography (Ginn and Company, 1928), 245. Ransom believed that smaller operations would prove viable on account of their proximity to cotton fields, which would allow them to market their seed locally. He wrote: “small mills, by reason of their nearness to the cotton fields, are able not only to market their seed without freights, but can dispose of their by-products at home, where they are needed by the farmers, stock-raisers and dairymen, at less expense than their larger competitors.”

Advantages of proximity, Ransom thought, would “probably be sufficient to sustain these small mills in any competition coming from the larger interests.”86Ransom, Great Cottonseed Industry, 19. This being said, many “operating refineries at centrally located points” controlled crude oil plants “located at the sources of the seed supply”87Lamborn, Cottonseed Products: A Manual of the Treatment of Cottonseed for Its Products and Their Utilization in the Arts, 37. and, as American geographer Albert Carlson observed a few decades later, “like all new industries, cottonseed processing appears to have attracted many who expected to make quick fortunes” but ignored broader logistical and commercial considerations.88Albert S. Carlson, ed., Economic Geography of Industrial Materials (New York: Reinhold, 1956), 405. Over time a number of these small mills did not survive the consolidation that followed changing market demand, improved processing technologies, and the advent of trucking. By the early 1950s, all processing plants in the cotton belt states were distributed on the basis of the local volume of seed production. As a result of the low density, bulkiness, and perishability of cottonseed, it was then typically uneconomical to ship the seeds “for crushing purposes more than 200 to 300 miles as a maximum.”89Carlson, Economic Geography of Industrial Materials, 405.

If whole cottonseeds did not travel far, their by-products typically did. From an early date, cottonseed cake and meal not only found ready markets both in the South and in other sections of the United States, but also in much of Western Europe. Brooks thus observed that “much of the Chicago and Kansas City dressed beef shipped to all parts of America in refrigerator cars is simply concentrated cotton seed meal and hulls,” while “many farmers near enough to the mills” fed cottonseed products to dairy cows near southern US cities.90Brooks, Cotton: Its Uses, Varieties, Fibre Structure, Cultivation, and Preparation for the Market and as an Article of Commerce, 330. Additionally, many early purchasers of cottonseed meal were located in northern European countries such as Denmark, England, and the Netherlands, where cheap American livestock feed (which included both cottonseed products and other cereals), combined with other animal feed from Eastern Europe, profoundly altered local agricultural production.

The case of Denmark is illustrative in this respect. In the second half of the nineteenth century, Danish farmers reacted to the availability of cheap animal feed imports by specializing in more lucrative livestock and dairy production. In the latter case, imported feedstuff proved absolutely essential to expanding production from summer to year-round dairying. Although limited quantities of American cottonseed meal had been bought before, Danish imports took off after a near failure of the Russian sunflower crop and a drastic reduction in the availability of sunflower cake. Ransom wrote admiringly that in the “famous Trifolium dairy in Denmark,” at the time the largest in the world, “15,000 head of milk cows are fed on cottonseed meal.”91Ransom, Great Cottonseed Industry, 57.

As a result of this open-trade policy, between the mid-1870s and the mid-1920s the Danish cattle herd doubled, the pig herd increased sixfold, and the chicken flock fourfold. By 1938, the British and German markets absorbed more than 76 percent of Danish exports (56 percent and 20 percent, respectively), then mostly consisting of butter, eggs, lard, and bacon. By embracing free trade, Danish farmers not only discovered “the fields of production in which they had the best opportunity to compete successfully with the farmers of the world, but they also were able to develop their own abilities, their agricultural production and marketing plants to almost functional perfection.” According to agricultural economist Karl Brandt, the result was “a most remarkable degree of culture and the art of decent living.”92Karl Brandt, The Reconstruction of World Agriculture (New York: W.W. Norton, 1945), 271–73.

Foreign markets played an even more significant role than local markets described by Ransom in providing early outlets for cottonseed oil, because American consumers were originally not fond of vegetable oils. On the plus side, upland cottonseed oil had many advantages over alternatives (including pima cottonseed oil) available to European mills and consumers between the late 1800s and the early decades of the twentieth century. Furthermore, parts of Europe were then struggling with a shortage of vegetable oils and dairy products. As Ransom put it, a “butter shortage, almost a famine, already exists, and it is said that in some parts of Europe the people have not seen real butter in twenty years.”93Ransom, Great Cottonseed Industry, 35 As a result, “during the early years of its manufacture cottonseed-oil was almost entirely exported to foreign countries, and export figures for those years represent very nearly the production of the country.”94Brooks, Story of Cotton, 23. Despite increased home consumption of cottonseed products (more than made up for by the increased domestic supply), the offerings of the briskly developing cottonseed industry had, as Ransom observed, “invaded the great olive groves of Europe and Asia” and were then “competing on equal terms” with the production of the traditional vegetable oil industries of those regions.95Ransom, Great Cottonseed Industry, 10–11. Brooks added that the best grade of upland cottonseed oil, “summer yellow,” was used in many European countries (at first mostly the Netherlands) in the preparation of dairy and lard substitutes and in salad oil, while the inferior grades were converted into soap (at first mostly in France).96Brooks, Story of Cotton, 362.

Although the evidence presented in this section gives but a glimpse of the rich history of the development of the cottonseed by-product industry, access to distant markets provided consumers in many locations with superior products that would not have been available to them if recovery links had remained local. Long-distance trade also made food production and provisioning more resilient overall and lessened the environmental impact of residual materials, which would otherwise have been destroyed locally.

Conclusion

Elinor Ostrom’s case on behalf of spontaneous and bottom-up communal polycentric governance has been criticized on the grounds that it is not scalable. While her critics have a point, their (typical) fondness for more direct and comprehensive government interventions in more complex cases of environmental degradation can be challenged through a better understanding of the circumstances that historically led to the development of complex value chains created around the development of by-products out of once problematic production residuals. As has been discussed in this chapter, both petroleum and cotton residuals were once the sources of significant local pollution. To many of Ostrom’s critics, the solutions to such problems would have revolved around the need for a top-down regulatory environment in which government legislation, monitoring, fines, and perhaps a cessation of operations would have played a significant role. An Ostromian analysis, on the other hand, would arguably start with an “it depends” perspective and proceed to characterize the entire action arena comprising the impacted commons and the human participants we have described. As the British political scientist Mark Pennington observed, “Ostrom’s work represents a direct challenge to [traditional ‘tragedy of the commons’] theorising because, while recognising that incentives matter, she argues that incentive structures are more varied and complex than conventional analysis assumes.”97Mark Pennington, “Elinor Ostrom, Common-Pool Resources and the Classical Liberal Tradition,” in The Future of the Commons: Beyond Market Failure and Government Regulation, ed. Elinor Ostrom (London: Institute of Economic Affairs, 2012), 23. In the cases we presented, however, it seems doubtful that either the authoritarian “stick” of the government or the decentralist “local solutions for local people” would have delivered better results than the drive to innovate and to make better products—and profits—out of production residuals. While these developments were asynchronous, polycentric, and spontaneous, they nonetheless required a very large geographical scale—indeed, one that quickly became much larger than that covered by the American federal government—to allow the development of the required coordination of various economic actors that eventually made it possible to solve local problems.

What is important is that polycentric profit, creativity, and property rights–driven processes required free trade and global markets to satisfy complex production schedules and needs. While our case studies do differ from those covered by Ostrom, they bear out one of her big-picture insights into all aspects of the development of governance solutions: “‘One-size-fits-all’ policies are not effective.”98Ostrom, “Beyond Markets and States,” 2. On the basis of these historical studies of spontaneous yet profit-driven environmental commons remediation, the key policy recommendation should repeat Ostrom’s warning that a dichotomous system is not sufficiently nuanced to provide optimal solutions for disposing of externalities. Ostrom described as dichotomous a system in which institutions and enforcement strategies are dictated either solely by the state (in the case of non-private goods such as security) or by the private sector (in the case of the market for private goods), and, according to her, such a division does not “adequately deal with the wide diversity of institutional arrangements that humans craft to govern, provide, and manage public goods and common-pool resources.”99 Elinor Ostrom, Beyond Markets and States: Polycentric Governance of Complex Economic Systems, (Nobel Prize Lecture, December 8, 2009), 409-10, available at https://www.nobelprize.org/uploads/2018/06/ostrom_lecture.pdf Analysts such as Milena Ristovska, who believe in a fundamental opposition between the search for increased profitability and environmental remediation, may find it both distasteful and odd that privately owned and privately managed businesses undertook the task of finding efficient ways to repurpose environmentally noxious waste.100Ristovska, “Role of the Business Sector.” But Ostrom’s Institutional Analysis and Development framework provides one necessary—although in our opinion insufficient—perspective that allows us to tease out the value that these diverse participants, each in their own way, found in not having to dump an externality in sensitive local environments. In the end, oversimplifications about the result of traditional business incentives, along with a reliance on poorly fitting assumptions, have the potential to result in top-down political approaches that are likely to prevent the spontaneous development of economically, environmentally, and socially beneficial solutions.

Table of Contents

- Introduction

- Chapter 1: Resource Governance in the American West: Institutions, Information, and Incentives

- Chapter 2: Self-Governance, Polycentricity, and Environmental Policy

- Chapter 3: Pacific Salmon Fisheries Management: An (Unusual) Example of Polycentric Governance Involving Indigenous Participation at Multiple Scales

- Chapter 4: Population Growth and the Governance of Complex Institutions: People Are More Than Mouths to Feed

- Chapter 5: Contracting and the Commons: Linking the Insights of Gary Libecap and Elinor Ostrom

- Chapter 6: The Environmental Benefits of Long-Distance Trade: Insights from the History of By-Product Development